Solution for 3C product Desktop Appearance AVI/AOI

Desktop module appearance AVI inspection is mainly used for defect detection of 3C product appearance, improving production line yield and the process control capability of manufacturers. Mainly detecting scratches, damages, pressure marks, broken edges, gaps, hidden cracks, burrs, warping, foreign objects, dirt, white spots, bubbles, pinholes, bumps and depressions, as well as component errors, leaks, reversals, excess, skewers, offsets, color differences, sizes, segments, etc.

Solution Features

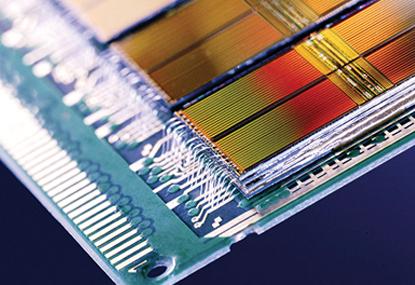

Optical+Algorithm

Independent intellectual property micro level high-precision high-speed optical imaging system, which eliminates interference from dust and micro particles on the top layer of the LCD screen to ensure imaging quality;

The core algorithm for defect detection with proprietary intellectual property rights and AI deep learning re evaluation algorithm are at the forefront of the industry.

Shock resistant+fast laser autofocus

Innovatively adopting an I-shaped seismic scanning mechanism and a marble seismic platform to achieve stable operation;

Adopting fast laser autofocus, it is not afraid of detecting object warping and deformation.

Original backend automatic report analysis system

Visualize data backup and data traceability, automatically implement image classification, facilitate user queries and audits;

Original backend automatic report analysis system, realizing report output and quickly submitting problem solutions for users;

Quickly filter out defective products in the production process, reducing customer complaints and cost waste.

Meet personalized needs

Programming is simple, fast, easy to configure, and a fast secondary development platform that can meet the personalized needs of different customers.